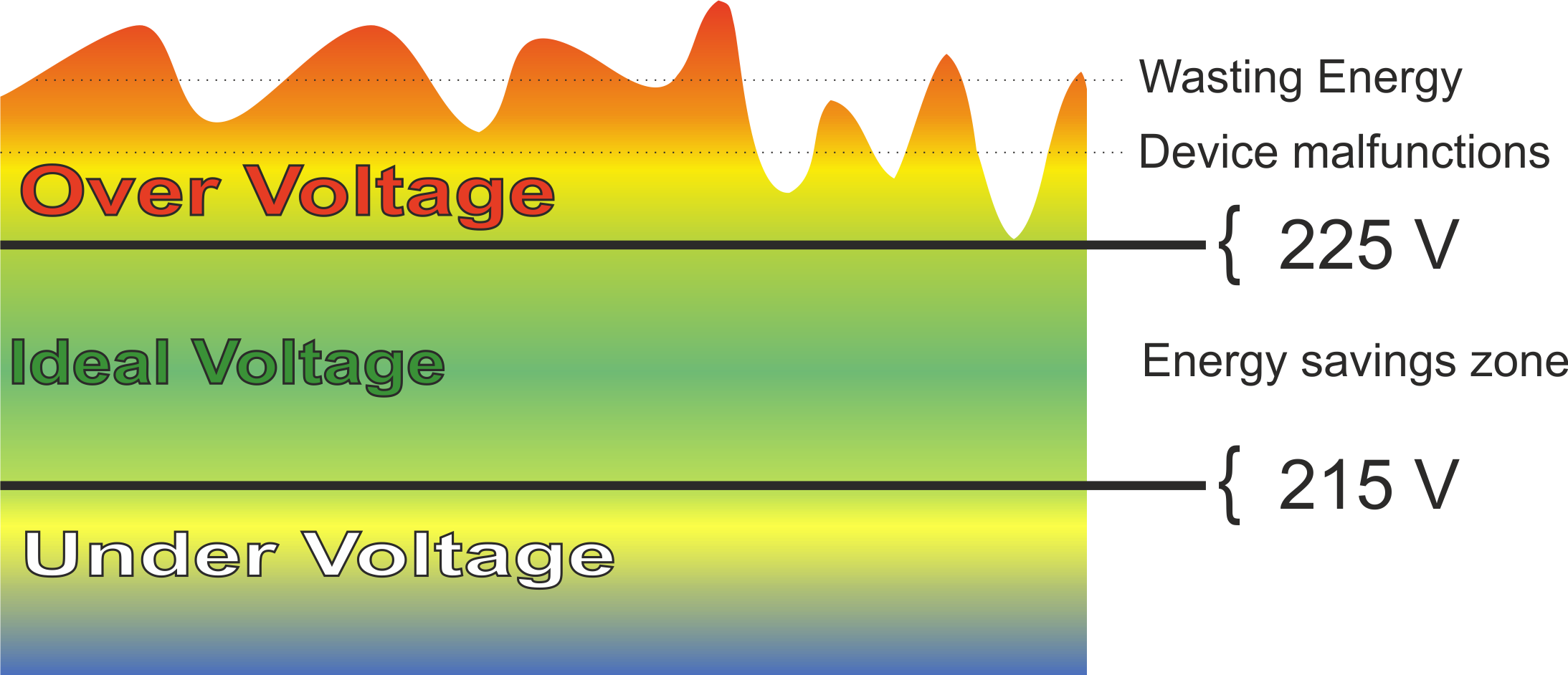

In recent decades, due to the rapidly growing demand for electricity and the increasing number of electrical appliances, the supply voltage has been constantly increasing in order to ensure an adequate level.

The EU ElectricityQuality directive and SupplyRegulations (EQS) defined a single grid voltage at 230V ± 10%, i.e., in the range of 207V - 253V due to changes in demand, infrastructure and other factors. According to the EQS and International Standard IEC 60038, each CE marked electrical appliance must operate safely within this range.

Electrical appliances with inductive properties such as refrigerators, air conditioners and compressors work more efficiently when the supplied voltage is regulated and stable.

LEC is a modern power regulator designed to control and stabilize the voltage supplied to lighting devices. By optimizing the voltage supplied to the light circuits and reducing by up to 42V, LEC reduces energy consumption and eliminates energy wastage.

The core of the LEC architecture is an array of custom designed transformers controlled by a microprocessor. The voltage control method implemented in all LECs is based on voltage-induced main voltage overvoltage technology to create the optimal output voltage.

Since it has both main and induced voltage, the sinusoidal waveform, the output voltage is purely sinusoidal. LEC does not create harmonic oscillations or electromagnetic interferences. Unlike multiturn autotransformers, the LEC design guarantees continuous voltage stabilization supplied to light circuits.

The ComEC consumption controller reduces the mains voltage by up to 20V and stabilizes it at a user-defined value.

ComEC delivers continuously read sinusoidal waves to all connected loads to improve active power and power consumption. In addition, ComEC reduces current and reactive power, which indirectly leads to a reduction in network losses on the devices and reduces operating costs.

1. Increased efficiency

For motors that operate at a lower load than the nominal one, by lowering the voltage within the permitted range (up to 20V from the mains voltage), the dynamic operating point will change and bring the engine to a more efficient state.

2. Increased power factor

Similar improvements can also be found with the executive. Increasing the efficiency will in fact reduce operating current and reduce losses in power lines.

3. Increase of engine operating point on magnetic hysteresis curve

By reducing the voltage, the engine operating point on the magnetic hysteresis curve moves from the saturated part to the linear one, reducing the internal losses of induction motors (namely iron losses).

Devices from the RSW manufacturer make it possible to measure and record consumption by measuring devices. This system can measure and record the consumption of electricity, gas, temperature, heat, compressed air and water.

The power of the device is counted the voltage x current (U x I) = power P

So if we have a 245V socket and the device needs 2A, the result is 490W (245 x 2 = 490)

But if you reduce the voltage to 220V then then 220V and the device still needs 2A the result is 440W (220 x 2 = 440)

In this example, we showed a 45W savings per unit per hour. This represents 32400W (32.4kW) savings per month.

© Alexoo Slovakia 2013 -

GDPR (General Data Protection Regulation)